We offer custom 3D printing from thermoplastics, resins, composite materials, as well as metals and alloys. We own the most advanced manufacturing technologies on the market, and our professional 3D printing services from plastics and metals are used not only by major companies, but also by small entities and individuals.

With us, you will find a wide range of cutting-edge additive manufacturing technologies, and you can rely on the rich experience of the Czech leader in industrial 3D technologies.

We offer fast and efficient production of end-use parts from functional industrial materials.

We will reliably manufacture custom-made parts for you, whether you need individual pieces or entire series.

With us you can create complex models that would be very difficult to produce using traditional manufacturing methods.

Our specialists will advise you on the appropriate material selection specifically for your application.

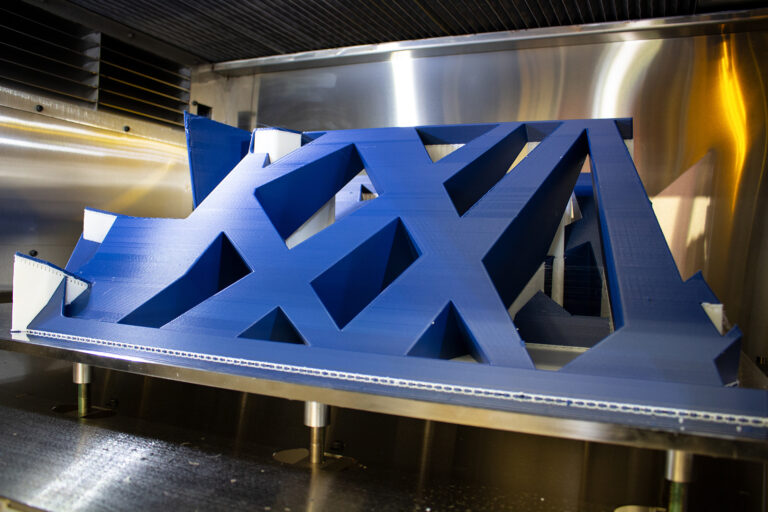

FDM is a 3D printing method that uses thin layers of molten material. The print head gradually takes up the thermoplastic wound on a spool, melts the material, and deposits it layer by layer onto a build plate. The advantage of this method is the single-piece or small-batch production of functional prototypes and strong and durable end-use parts. Short delivery times, low costs, minimal waste, and versatility of production make FDM the most widely used 3D printing technology on the market.

PolyJet is a patented 3D printing technology from Stratasys, which applies photopolymer material in layers up to 14 microns thick onto a substrate and then cures it with UV light. Printing with this method allows you to create parts that combine rich colours, transparency, or different degrees of Shore A hardness. You can even choose from a wide range of PANTONE colour shades. The technology can create smooth surfaces and process them to the finest details, making it ideal for producing realistic models or injection moulds.

Large-volume production with high precision and repeatability. This is how SAF (Selective Absorption Fusion) technology could be introduced, in which a layered polymer powder is sintered gradually. The technology offers high print quality, with an emphasis on precision and detail, as well as uniform, smooth surfaces. It can also efficiently produce parts with complex shapes. Low material consumption is ensured by the possibility of recycling excess powder during further printing. The technology can be used to produce various covers, connectors, or even eyeglass frames and has an important place in the automotive and consumer industries.

Programmable photopolymerization P3™ is a 3D printing technology for batch production. In this process, the material is gradually layered and cured using a high-resolution display. Thanks to this technology, you will achieve top precision, high-quality details, smooth surfaces and increased production capacity. In addition, the control of pressure, temperature and separation force during printing ensures that the first and last parts of the series are mechanically and geometrically identical. The parts can gain heat resistance up to 300 °C after tempering in an oven, which is why they are often used in the aerospace industry.

Wire-Laser Metal Deposition is based on the principle of precise layering of weld beads and belongs to the group of Direct Energy Deposition (DED) methods. Meltio’s technology is also unique thanks to its compact laser head with multiple lasers that are capable of processing welding wires sequentially and independently of each other.

Laser Powder Bed Fusion technology, commonly known as SLM (Selective Laser Melting) or DMLS (Direct Metal Laser Sintering), works on the principle of sintering a powder layer. A laser beam selectively sinter thin layers of metal powder to create parts directly from a CAD model. The finished part is stripped of excess powder, which can be filtered and reused in further production. The technology guarantees high manufacturing precision, processing down to the finest detail, and a short production cycle.

Binder Jetting technology is a comprehensive solution for the mass production of metal parts for end use without the need for tools. Each layer is formed by applying powder and then precisely jetting binder, which bonds the powder and creates the precise geometry of the part. After printing is complete, excess powder is removed by manual suction, which prepares the powder for recycling and further use. High-quality and reliable sintering in industrial furnaces removes the high-strength binder from the parts and ensures material homogenization. In addition to simplified post-processing, the technology also excels in high print resolution and flexible production capacity.

BMD™ (Bound Metal Deposition) technology is based on industrial Metal Injection Moulding (MIM) technology. Production is similar to FDM technology and uses polymer-bonded powder in the form of metal rods. The molten material is then applied layer by layer. The production process can be divided into three parts, where the printer prints the so-called Green Part, then the part is stripped of the binder and subsequently undergoes a sintering process. The main advantages of this technology are its ease of use and material replacement, adaptability of print settings, and safety during use.

Additive manufacturing allows you to obtain functional prototypes and end-use parts that meet high material requirements, especially in terms of precision, strength, and durability. We can create large and complex parts, metal components with internal cooling channels, realistic visual parts, and even models for the simulation of surgical operations that faithfully mimic human tissue, blood vessels, and bones.

We print from durable, high-quality industrial materials. Our offer includes a wide range of plastics, composites, metals, and alloys, and we always select the most suitable one for each application.

We have materials such as heat- and chemical-resistant Antero™ and ULTEM™, strong and durable ABS, Nylon 12 Carbon Fiber, and PC-ABS, flexible TPU, antistatic ABS-ESD7™, UV-stable ASA, and specialised certified materials from the Stratasys Validated family, and many others.

We have the latest 3D plastic printing technologies at our disposal, including FDM (Fused Deposition Modelling), PolyJet, SAF (Selective Absorption Fusion), and P3 DLP (Programmable PhotoPolymerization). Each of these technologies provides a unique approach to additive manufacturing and allows us to fully exploit the potential of 3D printing. Whether you need a single prototype or a series of parts, you can rely on us. Our services include one-off prototype production and series production of end products.

We use equipment with LPBF (Laser Powder Bed Fusion), BMD™ (Bound Metal Deposition) and Binder Jetting technologies, which enable us to quickly and reliably achieve the best results for your projects.

We also offer WLMD (Wire-Laser Metal Deposition) laser welding and cladding technology. This technology is unique thanks to its compact laser head with multiple lasers that are capable of processing welding wires independently of each other.

We are pushing the boundaries of intelligent and additive manufacturing with industrial 3D technologies. Whether it is rapid prototyping, reliable 3D printing of end-use parts or even serial production, you will find a wide range of cutting-edge additive manufacturing technologies with us, and you can rely on the rich experience of the Czech leader in industrial 3D technologies.

For over 30 years, we have been helping our customers meet the needs of the most demanding projects and redefine product design, development and production processes. Thanks to our extensive experience and team of highly trained experts, we enable you to do things efficiently and economically.

Contact us, and we will work with you to determine the best approach to help you achieve your goals.

Years on the market

Orders annually

Additive technologies

Satisfied customers